© 2016 All Rights Reserved - Rol-Flo Engineering, Westerly,Rhode Island, USA

Services

FORM ROLLING FLAT DIE SPECIALISTS

Flat die form-rolling technology is an art as well as a science. Rol-Flo’s

engineering staff uses proprietary calculators to qualify your production

parts. Our FAQ answers the most asked questions about flat die form-

rolling applications. Call or e-mail our engineering staff for detailed

information.

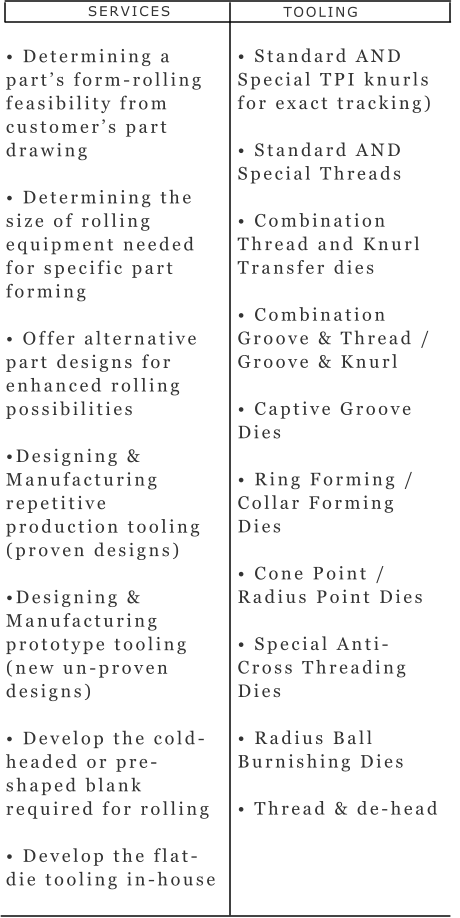

• Determining a part’s form-

rolling feasibility from

customer’s part drawing

• Determining the size of

rolling equipment needed for

specific part forming

• Offer alternative part designs

for

enhanced rolling possibilities

•Designing & Manufacturing

repetitive production tooling

(proven designs)

•Designing & Manufacturing

prototype tooling (new un-

proven designs)

• Develop the cold-headed or

pre-shaped blank required for

rolling

• Develop the flat-die tooling

in-house

• Standard AND Special TPI

knurls for exact tracking)

• Standard AND Special

Threads

• Combination Thread and

Knurl Transfer dies

• Combination Groove &

Thread / Groove & Knurl

• Captive Groove Dies

• Ring Forming / Collar

Forming Dies

• Cone Point / Radius Point

Dies

• Special Anti-Cross

Threading Dies

• Radius Ball Burnishing Dies

• Thread & de-head

SERVICES

TOOLING

The possibilities for Flat-Die Forming are endless. Contact us with your specific part

requirements and / or die needs and we will work with you in providing the solution.

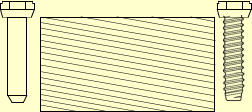

Tapping Screw Flat

Die M4.2-1.41 Type B

FORM ROLLING FLAT DIE SPECIALISTS

Flat die form-rolling technology is an art as

well as a science. Rol-Flo’s engineering staff

uses proprietary calculators to qualify your

production parts. Our FAQ answers the most

asked questions about flat die form-rolling

applications. Call or e-mail our engineering

staff for detailed information.

Services

The possibilities for Flat-Die Forming are endless.

Contact us with your specific part requirements

and / or die needs and we will work with you in

providing the solution.

© 2016 All Rights Reserved - Rol-Flo Engineering, USA